The spectrum ranges from hydraulic clutches for maritime drives, to pneumatic clutches for ship's winches, as well as special electromagnetic brakes for diving robots (ROV), in both civil and non-civil shipping.Whenever it comes to high-precision power distribution, HEID components are used.

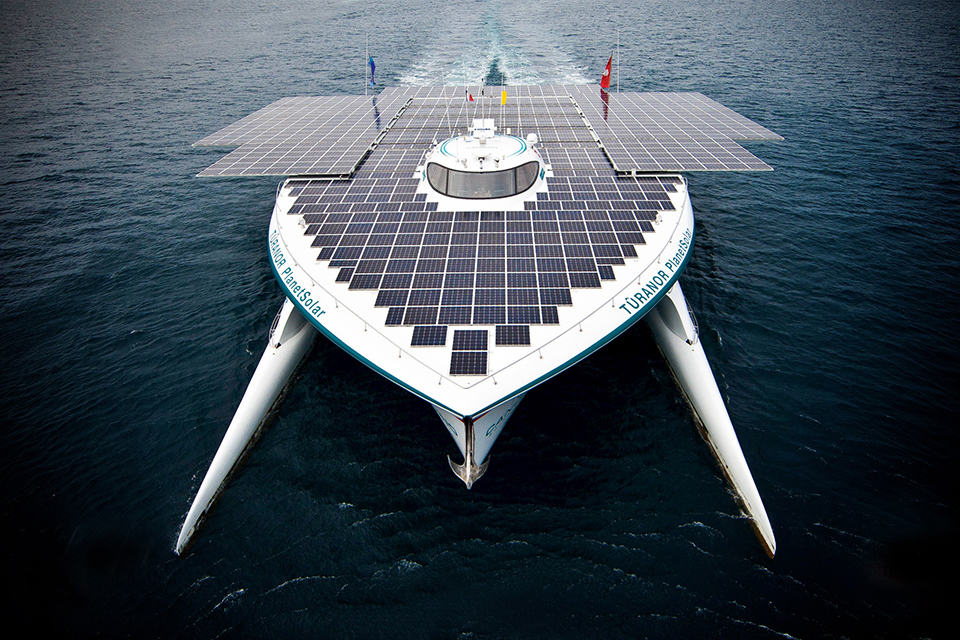

Planet Solar

Planet Solar

The Swiss initiators of Planet Solar have set themselves the task of proving to the world what can be done with the innovative electric drives. This is how the world's largest ship, powered entirely by solar energy, has emerged, which has achieved a couple records.

HED supplied the special toothed clutches for the adjustment of the solar panels.

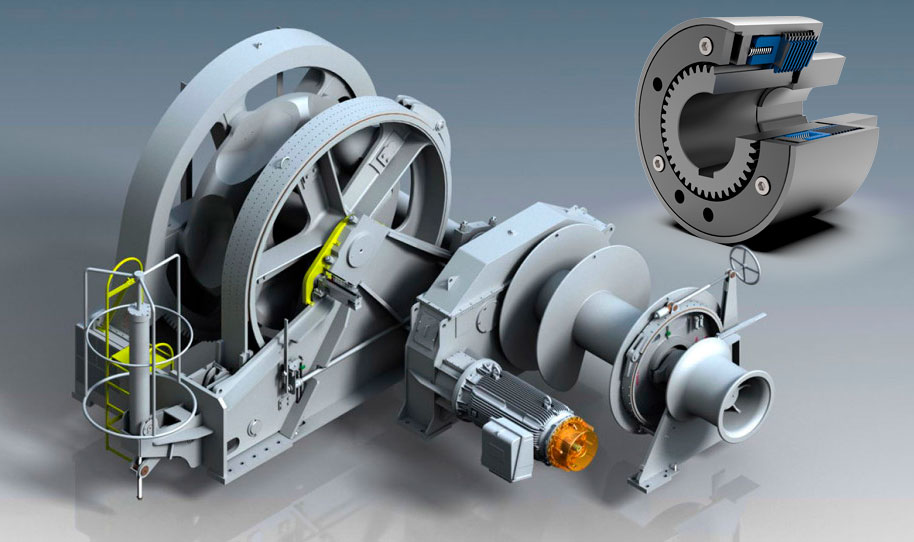

Anchor & Mooring Winche

Anchor & Mooring Winche

HEID overload safety clutches of the RLO-S series protect the drive system of anchor and mooring winches against torque peaks. The slip torque is set on the self-developed test bench from HEID with an accuracy of +/- 2%.

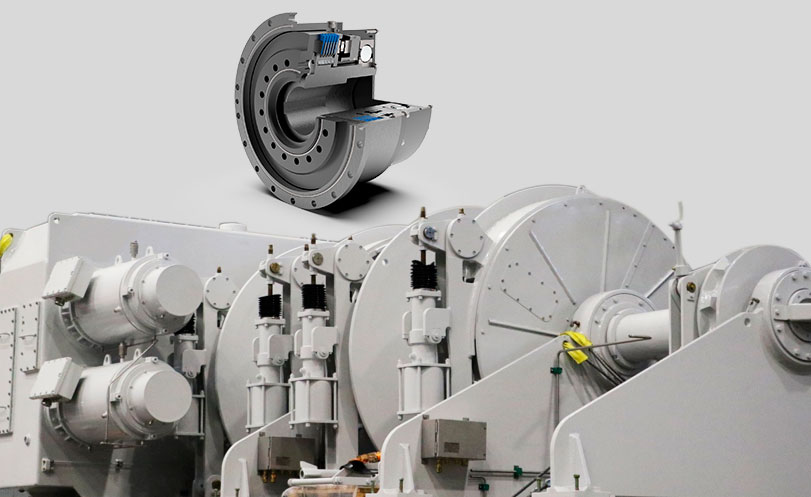

Escort Winche

Escort Winche

HEID has developed a special pneumatic clutch with a torque of 1.7 kNm for an industry leader in the field of maritime winches. This escort winch has a pulling force of 1000 kN.

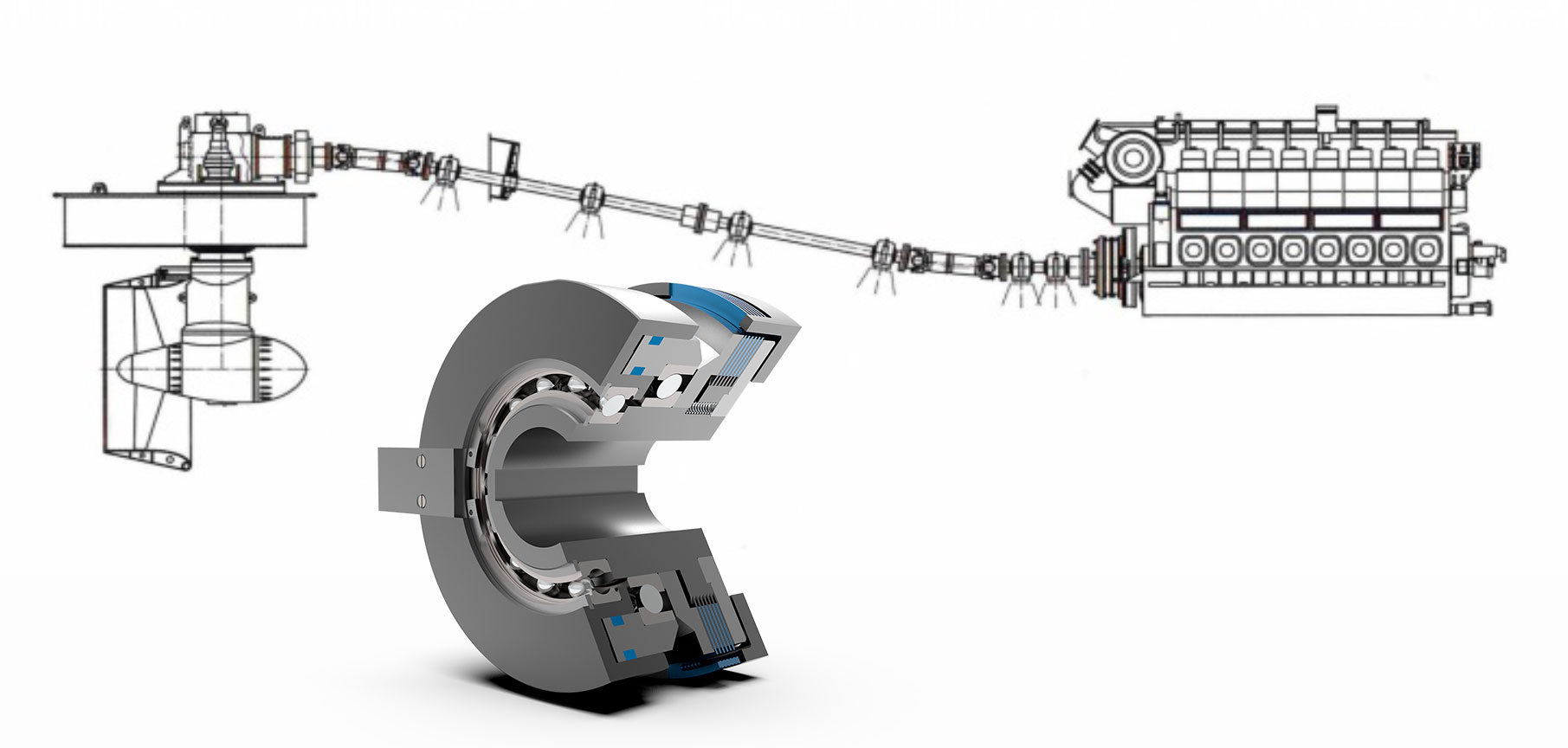

Azimuth Thruster…

Azimuth Thruster…

... are highly efficient ship propulsion systems that can be freely rotated, improve the maneuverability of ships and do not require a steering gear. HEID has further developed a hydraulic clutch from the HLS series for these drives and adapted them to these systems.

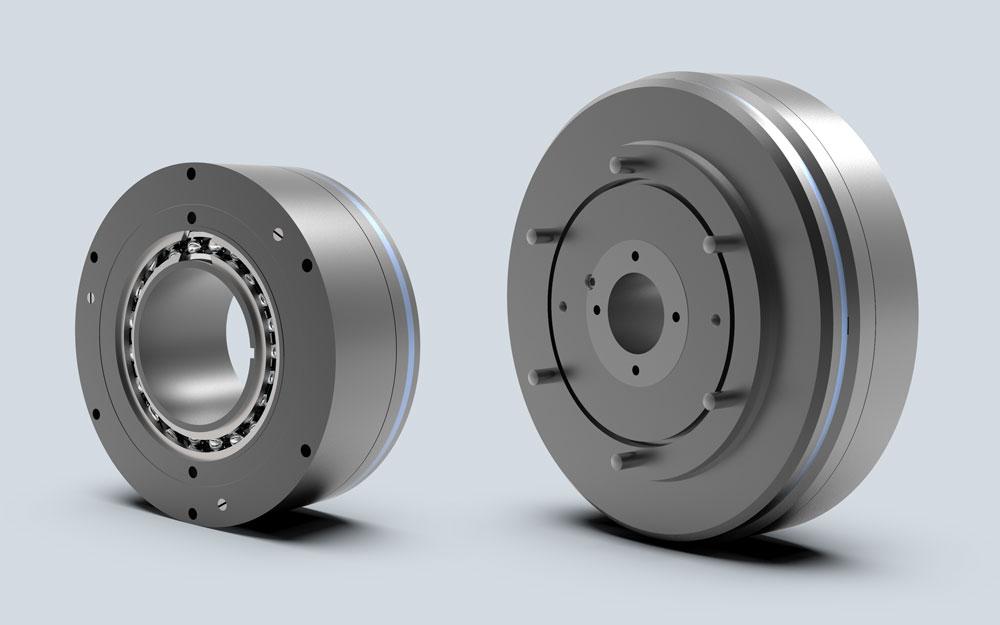

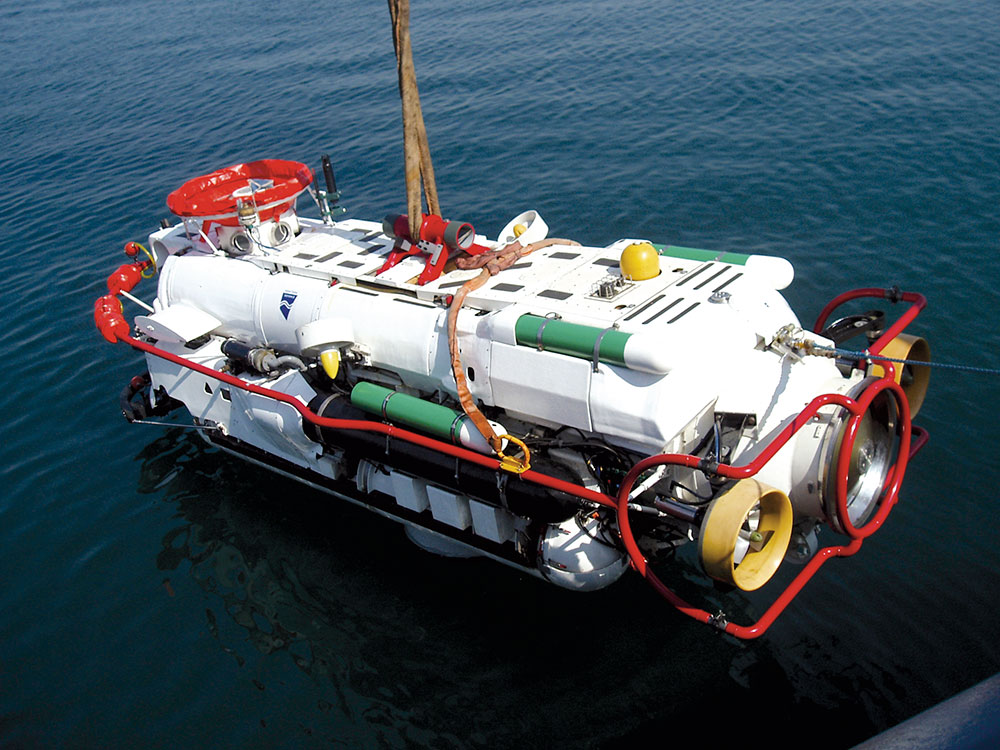

ROV – Remotive Operated Vehicle

ROV – Remotive Operated Vehicle

In recent years, HEID, together with a leading manufacturer for ROV (remotive operated vehicle), has newly developed a new type of brake for this deep-diving machine. In addition to the braking function, this brake also has the task of protecting the system from overloads.

The brakes built into the manipulation arms can be adjusted so that they slip in a controlled manner under a defined load.

In the meantime, there are other manufacturers who use this system as well.

Low En ergy

ergy

For a battery-powered research submarine in North America, HEID developed a special electromagnetic multi disc clutch of the FMOV type in a "LE" (low energy) version. Thanks to a special design and a specially developed magnetic coil, the power consumption of the clutch was reduced by 38 percent.